2026 special offers on stock presses. Email us for more info sales@hammerpresses.com

Metal Stamping Presses Photo Gallery

DOWNLOAD OUR PDF CATALOG BELOW FOR FULL RANGE OF MODELS

MECHANICAL PRESS MODELS

FOUR & DOUBLE POINT LARGE BED PRESSES

Providing the Metal Forming Industry with HAMMER STRENGTH ROBUST Presses for your High Demand Stamping Needs

S4 - Straight Side Four (4) Point

Extra Large Bed Presses. Eccentric Gear & Plunger Guided. Eight (8) Point Extra Long Taper Wedged Gib Guidance System. Monitored Recirculating Oil System. Best Press Components and Proven Press Controls. Rolling Bolsters, QDC & Automation Available.

Progressive Die / Transfer / Large Tooling

Up to 2500 Ton

S2 - Straight Side Two (2) Point

Large Bed Presses. Eccentric Gear & Plunger Guided. Eight (8) Point Extra Long Taper Wedged Gib Guidance System. Monitored Recirculating Oil System. Best Press Components and Proven Press Controls. Rolling Bolsters, QDC & Automation Available. Link Motion Optional

Progressive Die / Transfer / Large Tooling

Up to 2500 Ton

STD - Straight Side Two (2) Point

Heavy Press Frame Construction. Center Drive or Back to Front Drive / Crank or Crank-less Designs. Wide Side Windows. Eight (8) Point Extra Long Taper Wedged Gib Guidance System. Monitored Recirculating Oil System. Link Motion Option

Rolling Bolster & Automation Options.

Progressive Die / Transfer / Long Tooling

Up to 2000 Ton

DOUBLE POINT LONG BED PRESSES

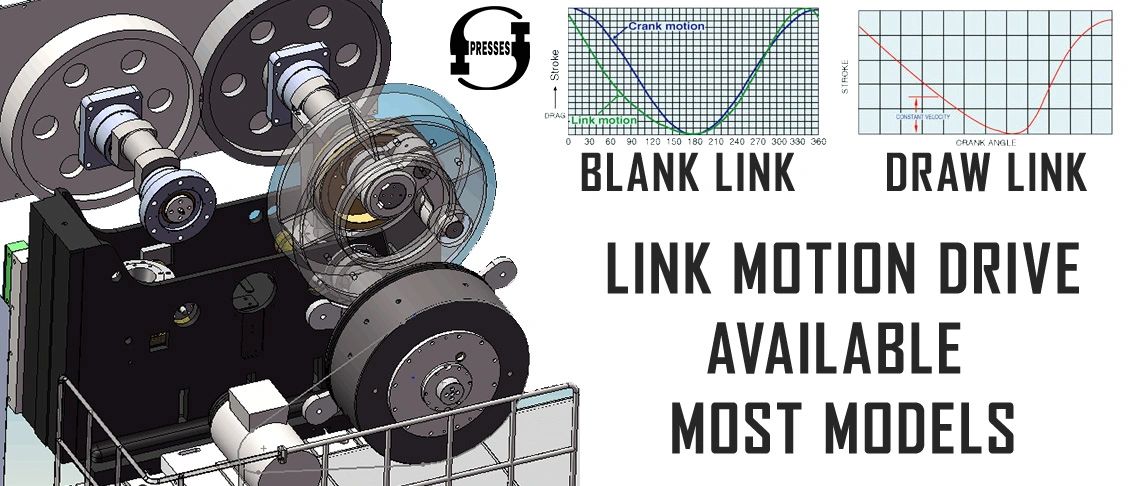

Large Part or Long Tooling / Progressive Die / Transfer Tooling / Link Motion Options Available on Most Models

CBL - Cross Bar Link Two (2)Point

Double Point Link Motion Soft Touch @ BDC to Increase Tooling and Press Life. Suitable for Coining and Heavy Blanking. Smooth Return to Top (TDC) Cycle after Breakthrough to Eliminate Slug Issues and Tool Damage. Cross Bar Knuckle Joint Transmission. Very Heavy Duty Frame Construction True Straight Side Box Column Frame. Eight (8) Point Gib & Plunger Guide Precision Slide Guidance

Blanking / Coining / Drawing / Prog Die

200-600 Tons

Long Bed Straight Side Press to Minimize Deflection. Heavy Duty Monoblock Frame Constuctions Six (6) Point Automatic Grease Precision Taper Wedge Gib Guidance System. Large Side Window Opening. Best Press Components and Proven Press Controls.

Progressive Die/ Transfer / Large die

160-600 Ton

Long Bed C-Frame Presses w/ Robust Frame to Minimize Deflection.

Six (6) Point Automatic Grease Precision Taper Wedge Gib Guidance System.

Open Die Area Space on All Sides. Best Press Components and Proven Press Controls.

Progressive Die/ Transfer / Large die

80-315 Ton

DOWNLOAD OUR COMPLETE CATALOG OF PRESSES / CALL TO SPEAK TO A TECHNICAL APPLICATIONS SPECIALIST: INFO@HAMMERPRESSES.COM

HIGH SPEED DOUBLE POINT PLUNGER GUIDED PRESSES

Long Progressive High Speed Tooling / Electrical Components / Motor Lamination /

VHD High Speed Double Point Straight Side

100-550 Strokes per minute. Available from 80-360 ton. Dynamic Balancing and Slide Counter-Balancing. Dual plunger guided slide and cast frame. Micro Adjustment Slide with hydraulic locking. Closed re-circulation oil lubrication system with cooling. Ideal for motor lamination stamping / Multi-cavity cupping / Scroll Slitting

APH High Speed Double Point Straight Side

150-800 Strokes per Minute. Available from 60-500 ton. Double Point High Speed Straight Side. Plunger Guided and weight balanced drive. Post Guided slide with hydraulic clamping lock for die height adjustment. Recirculating oil systems with cooling. Ideal for motor lamination stamping / Multi draw forming parts / progressive dies / coining and cupping

CHD & CHS High Speed Double and Single Point Cast Frame Straight Side

200 - 900 Strokes per minute. Available in double point long bed or single point from 25-360 ton capacity. Cast iron frame. Plunger Guided Patented drive design. Weight balancing drive system for vibration dampening. Post Guided slide. Recirculating oil systems with cooling. Electrical parts bending and forming / high speed blanking / motor lamination stamping

SINGLE POINT STRAIGHT SIDE PRESSES

Single Point Robust Straight Sides / LINK MOTION / High Speed Straight Sides

Single Point True Straight Side Construction

Eight (8) Point Extra Long Taper Wedged Gib Guidance System w/ Grease Lubrication

Tie Rod or Monoblock Box Column Heavy Duty Frame Construction. Wide Side Window Opening. Left or Right Transmission Drive Placement.

200-1000 Ton

Robust Single Point Straight side. Monoblock Welded & Heat Treated Frame Construction. Precision Taper Wedged Gib Six (6) Point Gib Guidance Grease System. Best Press Components and Proven Press Controls.

80-600 Ton

Single Point True Straight Side Construction Plunger Guided & Eccentric Shaft.

Eight (8) Point Extra Long Taper Wedged Gib Guidance System. Monitored Recirculating Oil System.

High Speed 150-200 SPM from 80-200 ton

SINGLE POINT STRAIGHT SIDE PRESSES & C-FRAME

Single Connecting Rod Robust Monoblock Straight Side Press. Variable Speed Motor and Drive. CE Safety Certification & JIS First Class. Wide Side Window Openings.

Six (6) Point Automatic Grease Precision Taper Wedge Gib Guidance System. Electronic Motorized Die Height Adjustment with LED Readout. Best Brand Components & Proven Press Controls

80-315 Ton

KL & KNL Knuckle Joint Link Single Point Straight Side

Single Point Link Motion Soft Touch @ BDC to Increase Tooling and Press Life. Suitable for Coining and Heavy Blanking. Smooth Return to Top (TDC) Cycle after Breakthrough to Eliminate Slug Issues and Tool Damage. Knuckle Joint + Link Motion Transmission. Very Heavy Duty Frame Construction True Straight Side Box Column Frame. Eight (8) Point Gib & Plunger Guide Precision Slide Guidance

Blanking / Coining / Drawing / Prog Die

200-600 Tons

Medium Duty, Cost Effective Durability. CE Safety Certification & JIS First Class.

Six (6) Point Automatic Grease Precision Taper Wedge Gib Guidance System.

Open Die Area Space on All Sides.

Best Brand Components & Proven Press Controls. Electronic Motorized Die Height Adjustment with LED Readout on Models 80 ton and Above

160-400 ton

DOWNLOAD OUR COMPLETE CATALOG OF PRESSES / CALL TO SPEAK TO A TECHNICAL APPLICATIONS SPECIALIST: INFO@HAMMERPRESSES.COM

SINGLE POINT GAP/ C-Frame

Adjustable Stroke / High Speed / Plunger Guided / Eccentric Shafts / Robust

Heavy Duty, Cost Effective Durability. CE Safety Certification & JIS First Class.

Six (6) Point Automatic Grease Precision Taper Wedge Gib Guidance System.

Open Die Area Space on All Sides.

Best Brand Components & Proven Press Controls. Electronic Motorized Die Height Adjustment with LED Readout on Models 80 ton and Above

15-315 ton

Plunger Guided Medium Speed. High Precision Slide Guidance System with Six (6) Point Taper Wedged Bronze Gibing and Plunger. Robust C-frame / Gap Design. Automatic Grease or Recirculating Oil Models. Electronic Motorized Die Height Adjustment with LED Readout on Models 80 ton and Above

25-160 ton

Adjust Stroke Length, Die Height & Speed. Heavy Duty Frame & Transmission Components. Mechanical Geared System with Pin in Crown to change Stroke Length. Built to JIS First Class & CE Safety Certification. Best Brand Components & Proven Press Controls

60-160 ton

SERVO GAP / C-FRAME & HIGH SPEED

Precision Servo / Bench Type Presses / Plunger Guided Precision

JDS - Servo Motor Direct Drive Four (4) Post Guided + Plunger

Servo Air Cooled with Drive. Completely Programmable Stroke Length and Speed (SPM). Four (4) Post Precision Guided Slide System + Main Plunger Guide.

Precision Servo Direct Drive

10-25 ton

High Speed C-Frame Plunger & Post Guided

Flywheel Driven Eccentric Robust Shaft

Power Take off Shaft on Left Side of Press for Mechanical Feeder Installation

Vibration Balancing System & Anti-Vibration Leveling Isolation Pads. Manual Die Height Adjustment with LED Readout.

25-60 ton / 200-800 SPM

JDC - High Speed Plunger Guided Bench Type C-Frame

Bench Type Smaller Tonnage High Speed C-frame Presses. Variable Speed Drive and Motor. Double Post Slide Guidance System + Plunger Guide. Flywheel Direct Drive to Eccentric Shaft

150-420 SPM Range

5-25 ton

DOWNLOAD OUR COMPLETE CATALOG OF PRESSES / CALL TO SPEAK TO A TECHNICAL APPLICATIONS SPECIALIST: info@hammerpresses.com

FORGING MECHANICAL PRESSES

HOT / COLD / WARM Forging Applications - Inquire About Our Strength In TURNKEY SOLUTIONS

HFP-X & HFP-XG - HOT FORGE ULTRA RIGIDITY

X-Type Design Gibs Fully Overcoming Thermal Expansion, Direct Driven By Flywheel, Semi-hermetic Clutch Mechanism, Recirculating Oil, Ultra Heavy Duty Rigidity Frame, Crank Journals & Transmission Drive. New Faster & Precise Cylinder Type Up-Acting Hydraulic Ejector System

400-4,000 ton

HFP & HFPG - HOT & WARM FORGE HEAVY DUTY HIGH SPEED

Horizontal & Vertical Bar Loading Forgings, Box-type thick Ridged frame ideal for Warm or Hot Forgings. Grease or Recirculating Oil Systems, Geared FP-G Ideal for Longer Parts & Vertical Long Alloy or Aluminum Billets, Rocker Arm or New Cylinder Type Up-acting Hydraulic Ejector System

400-2,500 ton

JKP & JKP-L - COLD FORGE KNUCKLE DRIVE

Cold Forge Billet Processing Knuckle Joint Press with Optional Automation, Hopper Feeder, Transfer & Tooling, Built to the same Heavy Duty Frame Rigidity Design as Hot Forging Presses. Rocker Arm Hydraulic Bed Ejector System, Hold Dwell of Stroke at BDC. Tonnage Display Monitor

400-1000 Ton

FORGING HYDRAULIC PRESSES & AUX EQUIPMENT

HOT / COLD Various Model Hydraulic Forging Presses / Forge Auxiliary Equipment / Let HAMMER Provide the Line

HFS & HF4P - HYDRAULIC FORGE

Models Available Suitable for Hot or Cold Forging. Versatile Performance. High Efficiency & World Class Brand Servo Motors, Valves, and Pumps. Press Fame is Built Heavy and Ridged for Long-Lasting, High Performance, & Reliable Machinery.

400-14,000 Ton

FBC - Bar/Billet Cutting Auto Line

Automatic Bar Feeder Billet Cutting Line Includes Press, Adjustable Length Sheer Tooling, Bar Stacker, & Auto Bar Feeder. Line can Cut Billets up to 4-5 inches diameter at Variable speed of 40-70 SPM Depending on Desired Billet Length. Increase Production, Capacity and Reliability.

CR - Rolling Reducer

2-3-4 Station Hot Billet Extension / Extrusion. Material Efficiency by Extending Short Cut Billets to 3-4 times the Length. Skilled Operator is No Longer Required with Optional Automation for Reducing Roller Available. Molds-Tooling for Roller is interchangeable. Easy to Operate, Adjust, and Install/Change Tooling-Molds.

DOWNLOAD OUR COMPLETE CATALOG OF PRESSES / CALL TO SPEAK TO A TECHNICAL APPLICATIONS SPECIALIST: INFO@HAMMERPRESSES.COM

DOWNLOAD OUR CATALOG BELOW FOR FULL RANGE OF MODELS

Learn More About Link Motion Drive Click Button Below

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.

EQUIPMENT IN STOCK

Contact us for a list of available quick delivery metal forming equipment / presses. info@hammerpresses.com